On Site chemical cleaning

Surface treatment/chemical cleaning on-site involves cleaning of installations before they become operational or after a production run, without dismantling them.

Possible treatments:

Degreasing, pickling, passivation, decarbonisation, lime and rust removal, solvent cleaning.

Materials that can be treated:

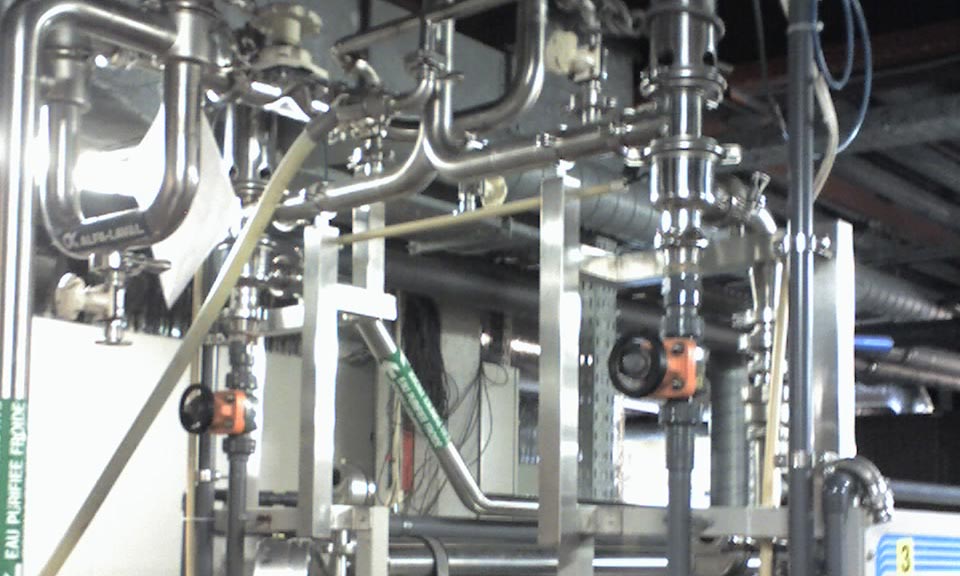

- stainless steel

- carbon Steel

- aluminium

- copper

- other alloys or mixtures of alloys

- plastics

Applications:

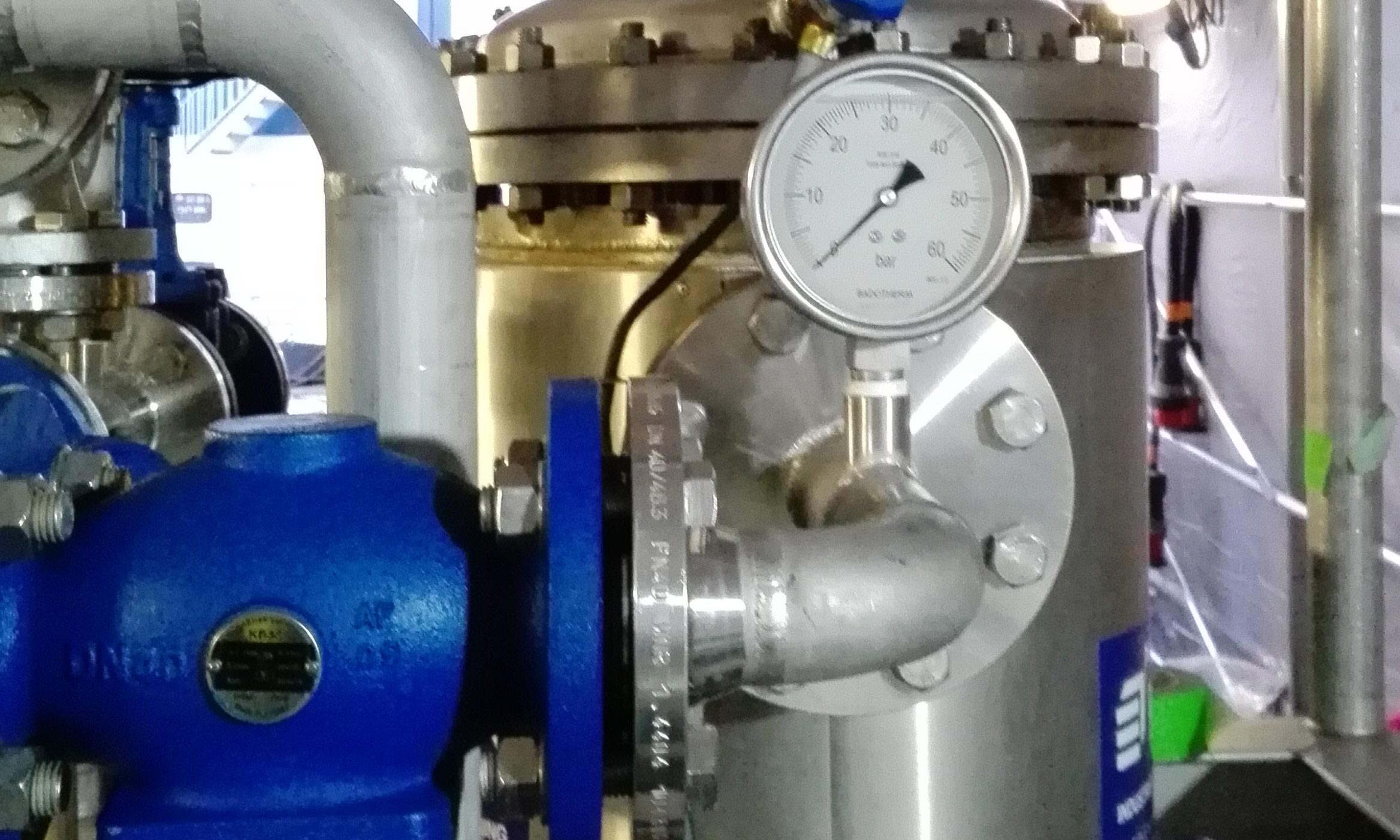

- pipe systems

- boilers

- heat exchangers

- storage tanks

- reactors

- distillation columns

- …

ROMARCO possesses more than sixty pump units with a capacity ranging from 15 to 750 m³/hour. If needed, our heat exchangers can heat up the treatment fluids to the desired temperature. Our filter installations can filter the treatment fluids from 500 to 1 micron. For the treatment of tanks and distillations columns: various types of tank cleaning machines. For solvent cleanings: completely closed circulation containers equipped with activated carbon filters and Ex circulation units.

In many cases, pipeline systems can be treated using one of ROMARCO's pig installations. Depending on the type of scaling in the pipelines, various treatment fluids can be injected. Separation is made by a pigs, a flexible polyurethane corks, which can be covered with a coating or a metal layer, depending on the piping material and the degree of dirt.

By the regular analysis and adaptation of our treatment fluids, we are able to guarantee that the installations entrusted to our care will be treated perfectly.

The waste streams can be stored in our tank trucks to be transported for legal treatment.

Treated installations or piping systems can be dried with one of our mobile compressors and dryers, who delivers filtered compressed air, 100% free of oil and water.

Contact us